1: Reduce total cost of ownership of heavy-duty fuel-cell vehicles

The reduction of the TCO for FC systems in HD applications is a cascaded result of several project outputs, and in general a product of higher production volumes of standardised fuel-cell modules (FCMs) enabled by a larger supply-side coupled with effective competition. A lower TCO will be a substantial motivation for heavy-duty end users, who operate under stricter budgetary constraints than private car owners, and in some cases with minimal profit margins, e.g. mass transit companies.

2: One single market for heavy-duty hydrogen applications

StasHH will provide an open standard for fuel-cell systems with clearly defined interfaces and few, well thought-out sizes for defined power levels, in order to pool together the smaller markets of buses, trucks, rail, ships, construction equipment, etc., and create a single market for heavy-duty zero-emission vehicles. This will enable economies of scale by enabling suppliers to sell a single product to multiple applications.

3: Ability to reach MW scale with modular units

The standard defined by StasHH will be modular and allow the installation of multiple, repeated standard units to reach higher power ratings; this will simplify the realisation of MW-scale power plants, which are relevant e.g. for fast passenger ferries, without having to build a custom power source for every new model. This will in turn expand the FCM market to applications demanding higher power ratings.

4: Fair competition among fuel-cell suppliers

Having customers operating on a standard platform will allow fuel-cell suppliers to compete more aggressively with each other, benefiting the market. Today, most deployments of fuel-cell technology are by OEMs who each choose a given FC supplier for their vehicles, e.g. Alstom and Hydrogenics. A standard interface for power delivery will enable OEMs to switch FC suppliers more easily, just like consumers can choose any brand of AA batteries they want for their appliances. This will make the elements of the powertrain independent from each other and interchangeable as a standard—just like compressors, motors, DC-DC converters, etc.

5: Lower research, development and innovation costs for OEMs

A significant cost for any deployment of heavy-duty fuel-cell technology is the R&D required to adapt the OEM’s platform to the FC supplier’s technology. The availability of StasHH’s standard interface will not only avoid a vendor lock-in, but will also expedite development of the OEM’s platform with well-defined interfaces for power, flows, cooling and data.

6: Cost reduction of fuel-cell systems by automation

It has long been calculated that mass production would have a major impact on the cost of FC systems. Being able to produce FC systems with well-defined interfaces will allow FCM suppliers to produce larger numbers of FCMs targeted at multiple markets at the same time, allowing for higher production numbers of the same FCMs and enabling automation of their production, leading to economies of scale and cheaper production costs. Higher production quantities will encourage more efficient FC designs with a reduced number of custom parts, which will lower the production cost even further.

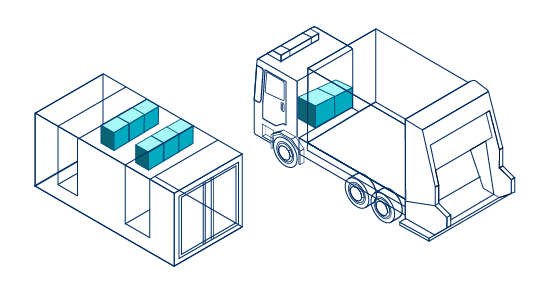

7: Improved supply chain

FC systems are often developed on a case-by-case basis, and operators usually need specially trained personnel to maintain these units; this is known to have caused difficulties and higher than expected costs e.g. in the maintenance of FC buses. With a standard interface as that provided by StasHH, however, operators will be able to simply swap a defective FC system for a spare one (possibly by a different FC vendor), and have the defective one repaired while the vehicle is still in operation; this will drastically reduce maintenance costs and downtime in FC deployments.